by Robert Walker, E.I.T. and Jesus Barreda, P.E.

SERRATED ANCHOR CHANNEL SYSTEMS

Hilti Anchor Channel with serrated channel lips (HAC-T) is a cutting-edge, easy to install cast-in solution for applications that require on-site adjustability and slip resistances along the long axis of the anchor channel resulting from seismic loads, lateral wind loads, or gravity loads if installed vertically. The innovative manufacturing technology allows HAC-T to offer slip resistances that require up to 58 percent lower installation torques than existing technologies without compromising the price point or performance of the anchorage. Because of the lower installation torque, the installation time per connection can be reduced and muscle fatigue may be avoided. HAC-T is fully covered by the International Council Code Evaluation Service Report 3520 (ESR-3520).

Cast-in anchor channel systems are a well-established technology in the construction industry and are frequently used for curtain wall, handrail, elevator, and other mechanical applications. Anchor channels are quick and easy to install because they are cast-in with the concrete and they overcome the drawbacks of other cast-in technologies by providing adjustability to the installer along the length of the channel.

Figure 1: Smooth Channel Lip vs Serrated Channel Lip

LONGITUDINAL LOADING WITH ANCHOR CHANNELS

Anchor channels are slotted connections that traditionally consisted of a smooth channel lip and smooth T-bolt head. Transferring of shear forces parallel to the long axis of the channel requires additional measures, as it is not recommended to rely on friction to resist such loads. Due to susceptibility to installation (i.e. grease on T-bolts), long-term T-bolt relaxation, and other factors, it is recommended to transfer longitudinal shear forces via a positive connection. A positive connection means that the system does not rely solely on friction but in mechanical interlock, bearing, or adhesive bond. Provisions for seismic loading for structures in seismic design categories C, D, E, and F were added to ICC-ES AC232 in 2015. AC232 requires a positive connection between the channel lip and T-bolt to transfer longitudinal shear forces. The first approved method for resisting these loads was filling standard anchor channel with HIT HY-100.

In a secondary stage, Hilti’s locking channel bolt (HBC-C-N) commonly known as notch bolts received an ICC-ES approval for resisting longitudinal shear loads without grouting the channel. The locking channel bolts have a specially designed and hardened head that “bites” into the channel lip via an increased installation torque, creating the positive connection needed to resist longitudinal loading; see figure 2. The HBC-C-N system is a code-compliant solution that offers slip resistance and gives flexibility to be used with standard channels, with the drawback of requiring higher installation torques.

Figure 2: HBC-C-N Locking Channel Bolt (notch bolt)

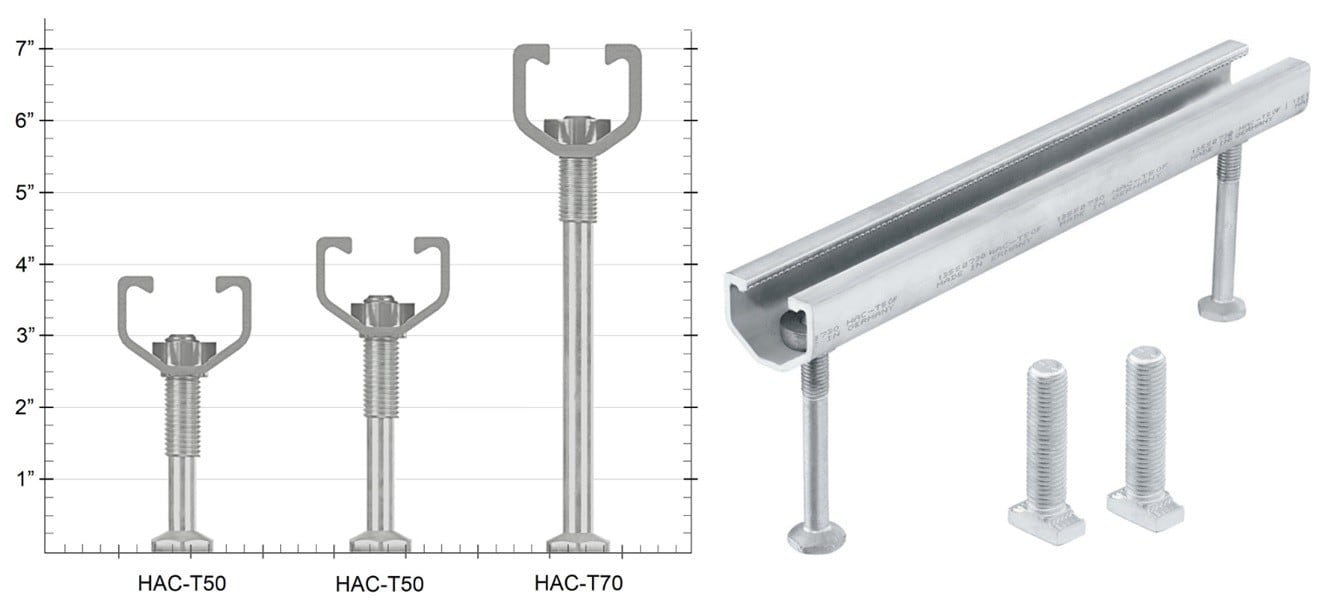

Finally, based on the feedback from installers, Hilti developed a serrated anchor channel portfolio (HAC-T) to offer an alternative code-compliant solution that reduces the installation torque by over 50% and without compromising cost and performance, making it a unique solution of its type. Hilti Serrated Anchor Channels and Serrated t-bolts come with pre-formed serrations. In contrast to the notch bolt with smooth channel profiles, the higher installation torque is not required for the serrated anchor channel system to create the mechanical interlock between the channel lips and t-bolt. Figure 3 illustrates the serrated anchor channel (HAC-T) and serrated T-bolt (HBC-T). Moreover, it provides a cross-section of the two standard HAC-T profiles and three different standard sizes. Length of the channels vary from 6 inches up to 19 feet.

Figure 3: Cross-sectional View of HAC-T50 and HAC-T70 and Isometric View of HAC-T and HBC-T

HAC-T BENEFITS

Hilti HAC-T serrated anchor channels with HBC-T serrated T-bolts are approved under ESR-3520 for strength design according to AC232 methods for cracked and uncracked concrete, normal and light-weight concrete, as well as seismic design categories C-F and with shear loading along the longitudinal axis of the anchor channel. The interlock between the serrations on the channel lip and the T-bolt provides longitudinal slip resistance using only about half* the installation torque required by alternative solutions and similar systems, speeding up the installation time while reducing muscle fatigue.

*Installation torque based on largest channel profile with M16 or M20 T-bolts.

Figure 4: Comparison of Installation Torque for Different Channel Bolts (T-bolts)

ADDITIONAL BENEFITS OF HAC-T

The benefits of the HAC-T lie in the innovative manufacturing process.

· The manufacturing process for the serrated lips requires minimal additional steps, making the cost of the HAC-T similar to its matching HAC. On the other hand, because the serrated T-bolts (HBC-T) do not require a special head-hardening process, the price of the serrated bolts is lower than that of the notch bolts. The result is a similar price point for both systems.

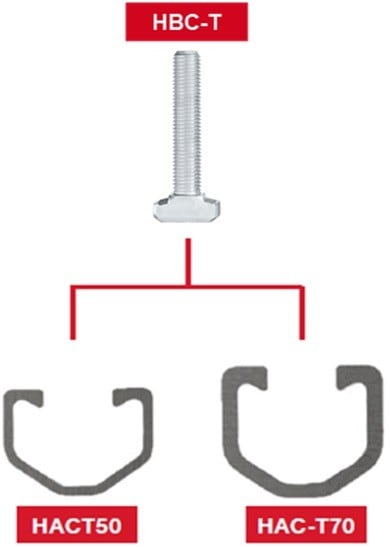

· Because the width of the channel profiles of HAC-T50 and HAC-T70 are relatively similar, the same size of serrated T-bolt is suitable for use with all Hilti serrated channels.

Figure 5: Compatibility of Hilti Serrated Channel Bolt (HBC-T) with HAC-T

HAC-T DESIGN AND PERFORMANCE

HAC-T is offered in two different channel profiles, HAC-T50 and HAC-T70, both of which can be ordered in varying lengths. The channel profiles and anchor sizes are identical to standard HAC-50 and HAC-70 except for the serrated channel lips. The HBC-T serrated T-bolts come in M12, M16, and M20 diameters with a variety of lengths. Each size of T-bolt is suitable for use with either size of channel. Slip resistance increases as T-bolt size increases and is higher for HAC-T70 than HAC-T50.

IS HAC-T RIGHT FOR YOUR PROJECT?

Things to consider when using HAC-T:

· HAC-T are offered in HAC-T50 and HAC-T70 sizes. The HBC-C-N can be used with anchor channel profiles HAC-40, HAC-50, HAC-60, and HAC-70. If a project can utilize HAC-40, the serrated channel solution will be HAC-T50. Likewise, if a project can utilize HAC-60, the serrated channel solution will be HAC-T70. For these cases, the benefits of lower installation torque may offset the added cost.

· HAC-T offers adjustability along the channel length in increments of about 1/8” compared to continuous adjustability of smooth channel profile.

· If the connection will require re-positioning of t-bolts and transferring of longitudinal and/or seismic forces, HAC-T is the way to go.

HAC-T RESOURCES

Strength design information for HAC-T can be found in ESR-3520. HAC-T is available for design in Hilti PROFIS Anchor Channel software for the most efficient and user-friendly design. Hilti’s Anchor Channel Engineers can perform calculations and assist with the design of specific conditions, providing you with the highest level of technical knowledge for anchor channel design. Further design information and commentary can be found in Hilti’s HAC Technical Guide. CAD files for HAC-T can be found in Hilti’s Online BIM/CAD Library.

PROFIS Anchor Channel Design Software: https://www.hilti.com/content/hilti/W1/US/en/engineering/software/profis/profis-channel.html

https://www.hilti.ca/software/software-for-fastening-system/r3604720

Hilti Online BIM/CAD Library: https://www.hilti.com/content/hilti/W1/US/en/engineering/software/bim.html

Hilti Anchor Channel Engineering Team: US+CA.HAC@Hilti.com