New ASTM Standard, UL Certification Program & Movement Capability of Hilti Firestop Systems

Why is movement important for firestopping?

Over the lifecycle of a building, movement can occur beyond the normal rigid support of penetrants through a rated assembly, which may impact the performance of firestopping. It is important to have a method to consider movement and the impact on firestopping.

The International Building Code requires a fire tested system for through-penetration firestopping in accordance with the ASTM E814 or UL 1479 standards. The UL 1479/ASTM E814 test standards indicate that “The extended portions of the penetrating items on the unexposed side are to be mechanically supported by a metal rack and secured at no more than two points.” Underwriters Laboratories (UL) listings require that all penetrants, such as piping, cables or any type of penetrant system, are rigidly supported to ensure there is no movement of the penetrant or firestopping. A firestop system that is rigidly supported does not carry load or the weight of the penetrating items and the penetrants are firmly fixed in place by a support system to minimize movement. Therefore, when the code requires a prescriptive system, we assume there is no movement within the firestopping.

There may be certain conditions, however, where movement occurs in firestopping over the life cycle of the building. Examples of movement of a through-penetration could be mechanical vibration in a piece of equipment over a long period of time or expansion and contraction due to thermal effects on a system. Slab deflection, mechanical forces, impact and water hammer can also occur over the lifetime of a building due to situations like blasts, high winds, mechanical systems, floor deflections or potential seismic events. An installed firestop system subjected to movement prior to fire exposure may not perform as intended in the event of a fire.

ASTM E3037, Standard Test Method for Measuring Relative Movement Capabilities of Through-Penetration Firestop Systems, was first issued in November 2016 to provide a standardized method to assess the ability of firestop systems to experience movement and continue to be relied upon to obtain their expected firestopping performance.

How did the new UL certification get established?

Testing standards are constantly developing and published to accommodate the needs of the industry and ultimately improve life safety. The movement standard development process began with designers, engineers, architects, and contractors who understood that movement occurs during the life cycle of a building and that movement can occur in firestop systems as a result. The fire protection industry experts and leaders, including Hilti, also wanted to ensure that firestop systems experiencing movement performed as intended in a fire scenario.

Based on this feedback and through a consensus process involving a range of stakeholders, the ASTM E3037 standard for Penetrations and Firestop Systems was developed. The new standard provides a standardized method to assess the ability of firestop systems to experience some degree of movement and continue to be relied upon to perform their firestopping function. The standard provides the testing criteria for movement of a firestop system with a specific amplitude and sequence using a movement cycling test apparatus. Samples are tested in two directions, the Z direction, which is parallel to the penetrant, and the Y direction, which is perpendicular to the penetrant (as shown in Figure 1).

Figure 1: “Simplifed Example of Test Assembly for Movement Testing”*

*Reference: ASTM E3037-20, FIG. 1

Once the standard was published, it was important to create a new firestop certification program. Certification programs allow a firestop manufacturer to obtain firestop listings certified for movement from a listing agency, such as UL. This process was again a lengthy industry wide collaborative effort lead by UL and Hilti, where Hilti contributed expert advice, testing and research to the efforts of developing this movement certification program.

How can we assess the effects of movement on firestop?

UL published the certification program for M-ratings in December 2019 with the intent of assessing the movement capability of through-penetrations such as pipes and cables passing through rated assemblies. This provides listed firestop systems that designers, architects, engineers, and contractors can use when there are anticipated movements of through penetrating items. These listings identify movement capabilities based on movement direction, pipe type and diameter, annular space, and firestop sealant depth (where applicable).

Systems are tested by cycling a certain number of times at a certain distance in accordance with ASTM E3037, the standard described above. The through-penetrations are tested in the perpendicular or parallel directions, or a combination of both, to represent movement that can be experienced over the lifetime of a building. Each cycle and distance are tracked until a maximum movement capability is attained. The system is then tested to the applicable test standard, such UL 1479/ASTM E814 to ensure the firestop system will perform as intended in the event of a fire, even after being subjected to movement. Note that a system cannot be certified for movement alone and must also be subjected to a fire test. If the desired fire ratings are reached during the burn test, the system can be certified for an M-rating as well as a fire rating.

These results quantify the amount of movement firestop systems can accommodate while still performing as intended in the event of a fire. The criteria are then documented in four movement displacement ranges, which are user friendly to the design team, for both the Z direction, parallel to the penetrant (shown in Figure 2), and the Y direction, perpendicular to the penetrant (shown in Figure 3). The movement range categories for the Y direction are (up to) 5%, 25%, 50%, and 100% of the annular space, and for the Z direction (up to) .25”, .5”, 1”, 3.21”.

Figure 2: Movement Test in Parallel

Figure 3: Movement Test in Perpendicular

How could you specify movement requirements?

There is now flexibility in unique scenarios, where movement is anticipated, to add the movement criteria, which is an exciting development new to the industry. Like ratings for other additional attributes of firestop systems, such as air leakage (L-rating) and water resistance (W-rating), the M-rating, can be included on the listing. With that rating, the movement criteria can be specified and if movement occurs within the tested range, the firestop system is expected to perform as intended. An example of a listing with L, W, and M-ratings is shown in Figure 4. Table 1 demonstrates the specific M-rating capabilities for the example listing.

Figure 4: Excerpt of Firestop System with M-Rating*

*Reference UL System No. F-A-2054, Table 2

Table 1: M-Rating Table for F-A-2054 System*

*Reference UL System No. F-A-2054, Table 2

It is important to note that M-ratings are currently specification driven requirements, as they are not within the prescriptive code language. Designers, engineers, and architects, however, can prescribe M-ratings in their specifications. During the design process, they may understand how much movement capability is needed for a certain scenario, such as excessive equipment vibration, potential thermal expansion or contraction, or a potential slab deflection.

Based on that information, in many cases, Hilti can provide a firestop system with an M-rating that accommodates the movement anticipated for that application. For systems that require movement the designer can include language in their specifications for minimum movement capabilities required, and the contractor can use this information to select a firestop solution.

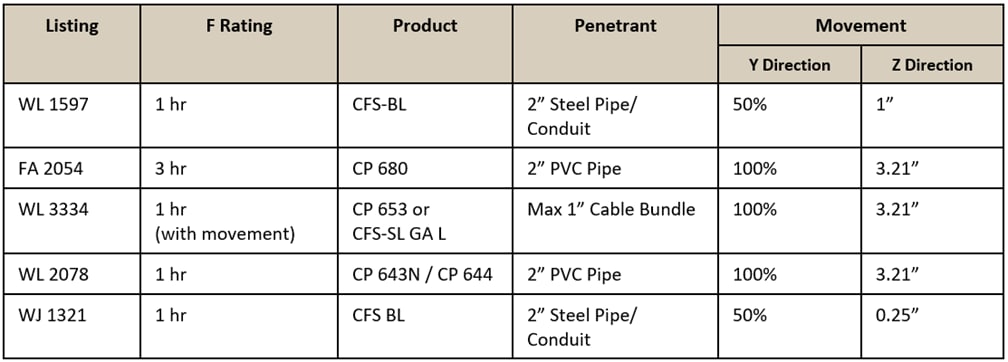

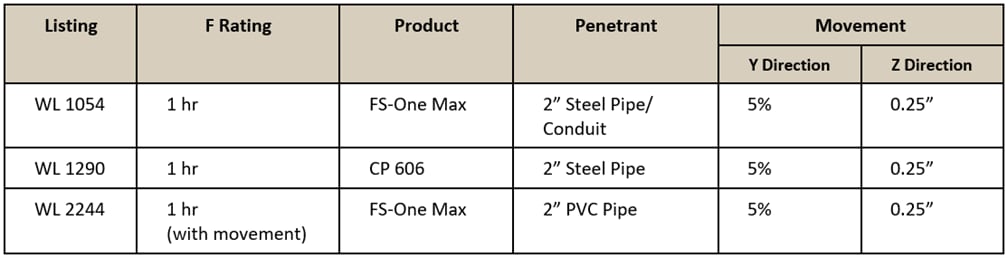

Designers can specify a required M-rating range for applications where movement is required or anticipated. Within specifications, they can reference a requirement for an M-rating system and tested to ASTM E3037. A schedule of listed systems with M-ratings can also be included on drawings and in specifications. Firestop details with M-ratings can be included on drawings. By specifying innovative firestop solutions that reduce the risks of movement of through-penetrations, designers can help ensure that movement is adequately accommodated in their designs. Some firestop devices, for example, allow up to 100% movement (reference Table 2), compared to 5% movement capabilities for some sealants (reference Table 3).

Table 2: Test Results firestop solutions tested for Movement - Devices*

*Table includes reference information for comparison only. See listings for full system details, requirements, and most recent information.

Table 3: Test Results firestop solutions tested for Movement – Sealants

Table 3: Test Results firestop solutions tested for Movement – Sealants

*Table includes reference information for comparison only. See listings for full system details, requirements, and most recent information.

Movement Capability of Hilti Firestop Systems

At Hilti, we have conducted extensive tests according to this latest industry standard. As a result, we provide firestop listings certified by the newly established UL certification program with movement ratings (M-ratings. With this we continue to commit to our ultimate purpose of helping save lives and improving building performance.

Being the first to market with eight (8) UL certified systems with M-ratings is important to us. Life safety in buildings relies greatly on firestopping that performs as intended. Hilti is committed to continuously contributing to improved life safety of buildings by developing and testing our firestop systems according to the latest industry standards. Hilti continues to collaborate with the ASTM task group and UL on continuous improvement initiatives to further enhance the new movement standard and certification program.

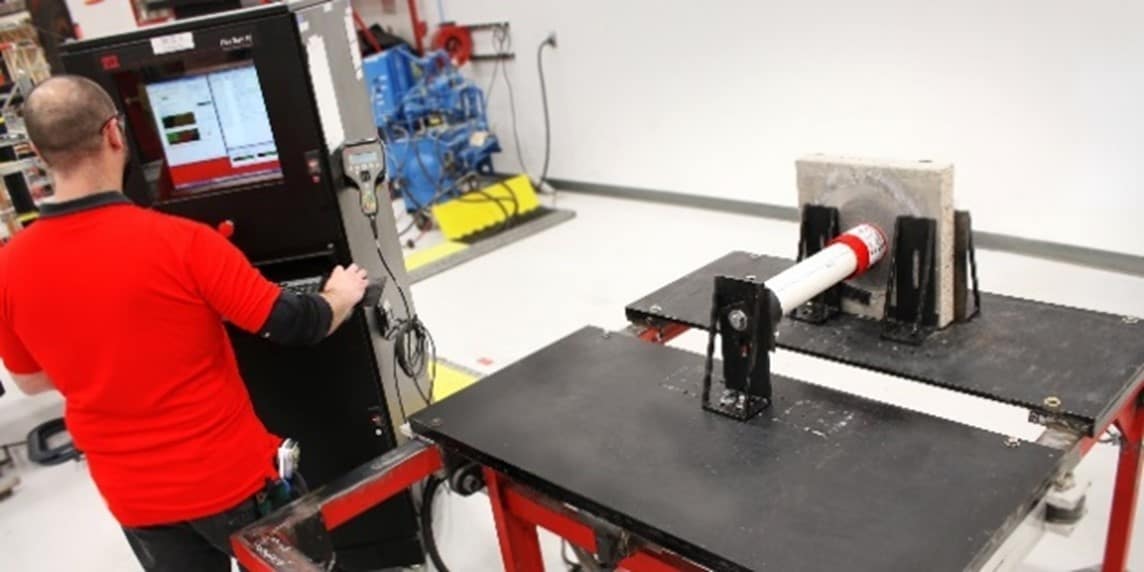

Hilti has several products and systems available to the design community for scenarios which involve movement. Hilti has successfully tested and certified a variety of our listings, from those that use sealants, such as FS-ONE Max, to those that use preformed devices, such as the speed sleeve CP 653 or firestop blocks CFS-BL (as shown in Figure 5).

Figure 5: A range of firestop solutions tested for Movement

Through our movement criteria research and testing, we determined that preformed devices, such as the drop-in devices, cast-in devices, and speed sleeves perform significantly better when it comes to movement than traditional sealant systems. These devices typically exceeded the thresholds of the limits set by the standards, and as a result, for firestop systems where movement is critical, pre-formed devices would be recommended.

Visit Hilti’s firestop movement resource page which will help direct you towards several useful resources, such as certified listings for movement. For any other questions, please visit https://ask.hilti.com/ or reach out to your local Hilti technical representative or our customer service team.

Learn More about Hilti’s Through-Penetration Firestop Systems Tested to Withstand Movement here: