Revisions to Acceptance Criteria AC01 and AC58

Post-installed anchors are often a contractor and engineer preferred method for connecting to masonry due to their ease of installation. However, despite the high relative use of post-installed anchors to cast-in anchors in masonry construction, the acceptance criteria for post-installed anchors into masonry base materials and the masonry reference code (TMS/S304) have not seen significant revisions or updates since the early 2000s.

This has resulted in stagnant testing and design methods available to engineers for their connection design. In 2020 and 2021, the International Code Council Evaluation Service (ICC-ES) passed significant revisions to Acceptance Criteria AC58 for Adhesive Anchors into Cracked and Uncracked Masonry, AC01 for Mechanical Anchors in Cracked and Uncracked Masonry, and AC106 for Predrilled Fasteners (Screw Anchors) in Masonry Elements to help correct the outdated methods for testing and designing post-installed anchors into masonry.

The compliance dates for these revisions to be implemented by the industry were April 15, 2023 for AC58 for adhesive anchors and February 16, 2024 for AC01 for mechanical anchors. The revisions impacted the testing protocol for post-installed anchors, remove impractical tests, provide a consistent method of assessment similar to the assessment for installation into concrete, and adjust the design procedures to what is consistent with the state of knowledge and practice in the anchor industry. Key revisions include:

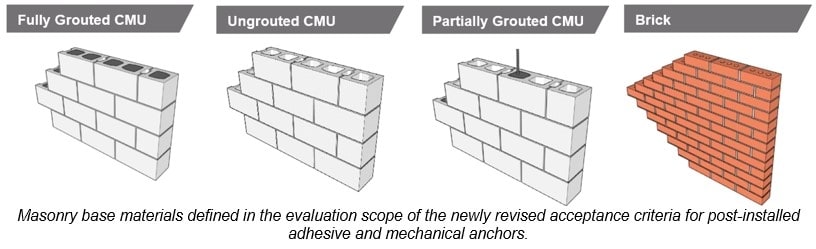

- Clarification of the types of masonry systems included in AC01 and AC58 such as: fully grouted concrete masonry units (CMU), partially grouted CMU, ungrouted CMU and clay brick.

- The adoption and adaptation of ACI 318’s Concrete Capacity Design (CCD) method of post-installed anchors into masonry base materials.

- The inclusion of cracked masonry testing and evaluation.

- The consolidation of AC106, the separate acceptance criteria for mechanical screw anchors into masonry base materials, into AC01, creating a single acceptance criterion for all mechanical anchors installed into masonry base materials.

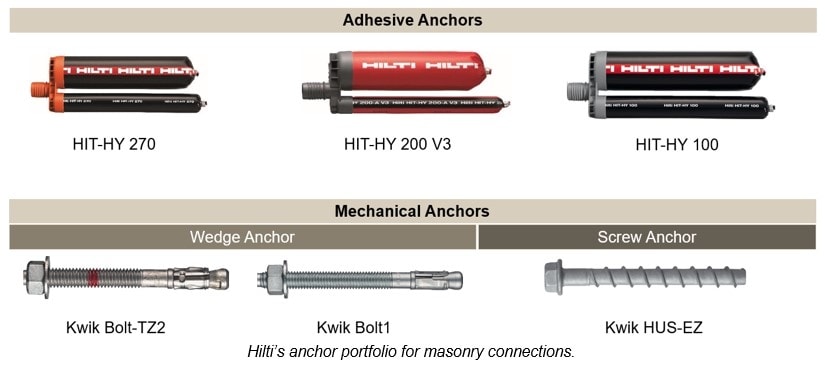

Hilti has spent the last two years re-testing our full masonry anchor portfolio of both mechanical and adhesive anchors to meet the requirements of the new acceptance criteria to support engineers in their compliance efforts with the model building code. We are also the first manufacturer with an Anchoring-to-Masonry software that supports the new strength design method to help engineers simplify the implementation of the new acceptance criteria in their designs.

Understanding how the Model Code and the Acceptance Criteria work

Understanding how the acceptance criteria works under the International Code Council is critical to understanding how these updated acceptance criteria changes affect an engineer’s design process when connecting to masonry base materials.

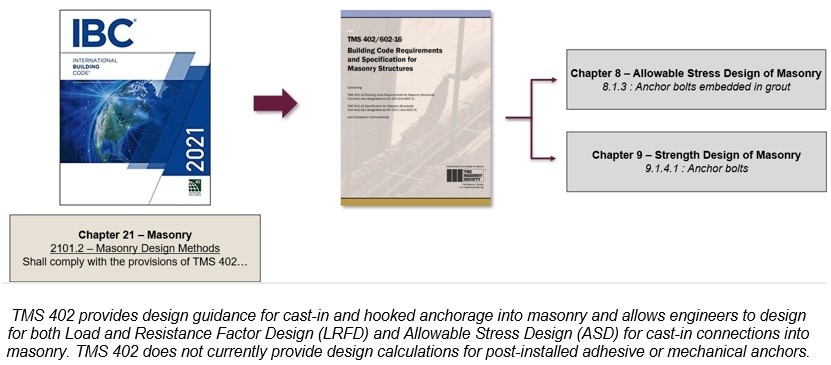

Per the International Code Council, the model building code establishes the minimum requirements for building systems using prescriptive and performance-related provisions. The provisions of the model code are founded on broad-based principles of design and construction. The model building codes refer to certain reference codes, such as The Masonry Society (TMS) 402 Building Code Requirements for Masonry Structures, to further support certain types of construction. However, the model building codes and reference codes are not all encompassing of every construction method. Thus, Section 104.11 of the International Building Code allows for alternative materials, design, or construction methods provided that any such alternative method of construction, design or material has been approved. For example, TMS 402 supports the design and specification of cast-in anchors into masonry base materials but does not include comparable provisions for the design or post-installed anchors into masonry base materials.

Thus, an acceptance criteria was developed for adhesive and mechanical anchors and published by the International Code Council Evaluation Service (ICC-ES), a subsidiary of the ICC, to provide a consistent method of testing and design of post-installed anchors into masonry base materials that demonstrate compliance with the model code. A post-installed anchor tested to the evaluation scope of the acceptance criteria receives an evaluation report that contains information about the product and its scope of use for an application. An evaluation report contains information about the building product so that a design engineer can design the anchor for their application in a masonry base material and so that a building official can verify that the product submitted for use on a project is appropriate for the relevant building code. Evaluation reports from a 3rd party evaluation service, such as ICC-ES or IAPMO-UES, means a manufacturer must submit and be tested to the same tests allowing for consistency for easy comparison.

An important note for engineers, the update and revisions to the acceptance criteria are retroactive for all model codes listed in the evaluation report of the product being evaluated. In the case of the revision to AC01 and AC58 discussed in this article, on the defined compliance dates, ICC-ES removes the product test reports that were per the old acceptance criteria. If an engineer chooses to design a post-installed anchor per the data provided in an old evaluation report, the data is only manufacturer’s data and not an updated 3rd party test report supported by ICC-ES.

New masonry base material scope and conditions

One major revision to the new acceptance criteria is the better-defined scope of the masonry base materials used during an anchor evaluation. With masonry components being manufactured with a variety of shapes, sizes, materials and in both hollow and solid configurations, the anchor system selected must be carefully matched to the application and base material used in the application. Engineers may observe more specific base material strengths and characteristics used during an anchor evaluation, allowing them to better evaluate the data provided in an evaluation report. The covered base materials include fully grouted CMU, partially grouted CMU, ungrouted CMU and clay brick.

Additionally, design engineers can expect the inclusion of cracked masonry data to the testing criteria of AC01 and AC58, thus allowing engineers to design their masonry anchors for cracked conditions. Prior to the acceptance criteria revisions in 2020, cracked masonry fell outside of the scope of the document. Since post-installed anchors may be adversely affected by the presences of cracks in masonry due to flexural stresses, engineers will have supporting design data for anchors in cracked and uncracked masonry.

Compared to concrete, where there are multiple applications where cracking may occur, modern CMU construction has more limited applications to where an engineer may wish to consider cracking in their anchor design. Common applications where an engineer may wish to evaluate their condition as cracked are:

- Areas where seismic loading may be considered, such as seismic design Categories C-F

- Areas with high wind forces

- Diaphragm connections

- Shear walls

Strength Design Method (LRFD) for post-installed masonry connections

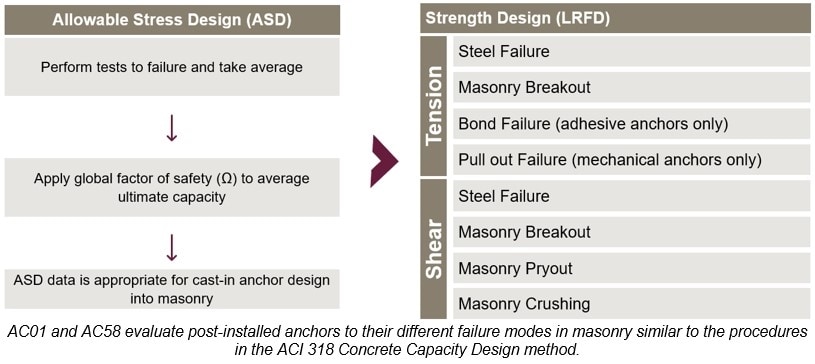

Before the recent revisions to the acceptance criteria, evaluation method for post-installed masonry connections was to use Allowable Stress Design (ASD). ASD is based on testing post-installed anchors to failure, then applying a global safety factor to reduce capacity of the anchor to an allowable load for design.

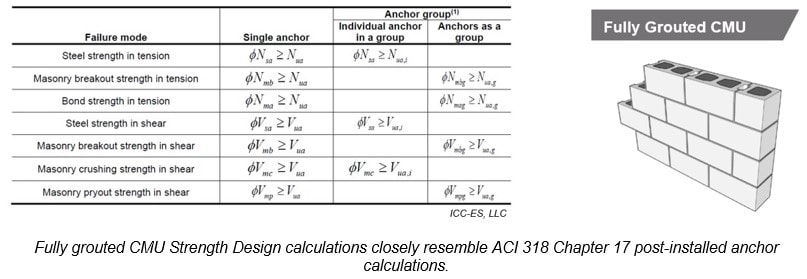

The revised testing method in the acceptance criteria has adopted the framework of the Strength Design method from ACI 318 Chapter 17, with only a few modifications specific to masonry base materials, allowing for anchors to be evaluated to separate failure modes rather than ultimate loads. The corresponding design method for post-installed anchors has been revised to the Strength Design (LRFD) method which uses testing to evaluate the multiple failure modes in tension and shear which mirrors the ACI 318 Concrete Capacity Design (CCD) method. The method assigns specific strength reduction factors to each of several possible failure modes, provides predictions for the strength associated with each failure mode, and compares the controlling design strength with factored loads. Engineers can optimize their anchor designs to the controlling failure mode like the current method of anchoring to concrete provisions provided in ACI 318 Chapter 17.

Design for fully grouted CMU is the most similar to ACI 318 Chapter 17 post-installed anchor calculations.

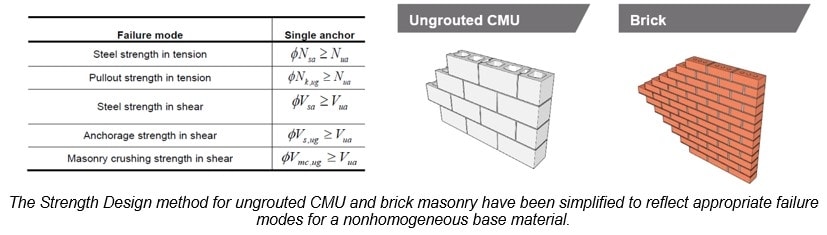

Anchor design into ungrouted CMU and brick masonry base materials also adopts the framework of the LRFD method from ACI 318 Chapter 17 with slight adjustments to account for the nonhomogeneous condition of the base material.

The design of post-installed anchors for partially grouted CMU requires extra detail and care by the engineer. Where grouted cell locations are known, grouted CMU provision may be used and ungrouted CMU provisions in ungrouted cell locations. Where grouted cell locations are unknown, ungrouted CMU provisions must be used.

Additional changes

Prior to the revised AC01 for Mechanical Anchors in Cracked and Uncracked Masonry, there existed two Acceptance Criteria for mechanical anchors. AC01 covered the evaluation and design method for wedge anchors into masonry and AC106 covered the evaluations and design method for screw fasteners into masonry. The revision of AC01 has consolidated the evaluation and design method of all mechanical anchors into a single acceptance criterion.

Engineers will also observe a few small differences between the k-factors for post-installed anchors in masonry compared to concrete base materials. The k-factors given for anchors designed into masonry will be lower compared to those same anchors in concrete to account for the inhomogeneity of masonry materials in breakout. Breakout cones for masonry base materials can be greatly influenced by the presence of head joints (vertical joints between CMU block) and bed joints (horizontal joints between blocks) of the wall. Like in the Concrete Capacity Design (CCD) method for concrete, a square area is determined for breakout and bond influence, with edges and closely spaced anchors reducing the overall influence area. Unique to CMU construction, head joints also need to be considered when determining the influence area.

Additionally, for anchors loaded in shear, engineers will need to consider masonry crushing in their post-installed anchor design. The masonry crushing equation has been adopted from the cast-in anchor calculations provided in The Masonry Society (TMS) 402. Masonry is typically a softer material than concrete when exposed to high shear loading and the steel anchor may crush and sink into the masonry block which is now accounted for in the new acceptance criteria.

Simplify transition from ASD to LRFD

Hilti’s PROFIS Engineering Suite software is a user-friendly, cloud-based application that helps make designing post-installed anchor connections easier. With the revisions to the Acceptance Criteria, the Anchoring-to-Masonry design module has been updated to support as engineers transition their designs and existing masonry details from ASD to LRFD for post-installed anchors. Engineers may easily transition their design to the guidelines of the new Acceptance Criteria, which will support their compliance with the model building code. The software allows engineers to select multiple masonry types such as grout-filled CMU, ungrouted (hollow) CMU, and clay brick, and it supports the design of Hilti adhesive and mechanical anchors into cracked and uncracked masonry conditions.

Hilti’s existing adhesive and mechanical anchor portfolio for masonry connections has been tested to the new acceptance criteria making anchor selection simple and helping to alleviate concerns about model building code compliance as the industry transitions to the new acceptance criteria.

Summary

The revisions to both AC01 and AC58 now mirror the ACI 318 Concrete Capacity Design (CCD) method and engineers can now better select their post-installed anchors for their exact application with the inclusion of well-defined base materials and base materials conditions. While the transition supports optimized connection design by allowing engineers to design to different failure modes, the revised LRFD calculation method is more extensive than the older method of ASD. The compliance dates for these revisions to be implemented by the industry are April 15, 2023 for AC58 for adhesive anchors and February 16, 2024 for AC01 for mechanical anchors. Manufacturers must have completed testing and evaluation of their products before these dates to retain their Evaluation Service Report (ESR). Hilti has already tested and published new reports for all existing anchors appropriate for connecting to masonry. As the industry transitions to these changes with the acceptance criteria, design engineers can utilize the PROFIS Engineering Suite software Masonry Design Module to support a quick and easy transition from ASD to LRFD with post-installed anchors tested to the new acceptance criteria.

Resources

PROFIS Engineering Software Suite

Masonry Anchor Strength Design Guide

Post-Installed Anchor Selector Charts